About Us

Products

Corporate news & Activities

Melt wood chips with chemicals and process them into wood pulp. When wood pulp is chemically reacted, it becomes transparent cellophane film.

This is the main component of the adhesive, It is made by purifying and solidifying the rubber tree sap.

This is the tackifier of the adhesive. It is plant-derived resin such as pine resin.

The raw material of cellophane is a wood chip. From the wood chips you can clump up vegetable fibers called “pulp”. By melting the pulp to cause a chemical reaction, a transparent cellophane film is made. The cellophane is created in a specialized factory for cellophane manufacturing.

The main raw material of the adhesive is natural rubber which can be taken out from the rubber tree. Cut the lumps of natural rubber that arrived from the production area, stretch them many times with rollers and process them thinly and softly. Put the processed rubber in a kettle together with natural resin and stir for about half a day to prepare an adhesive.

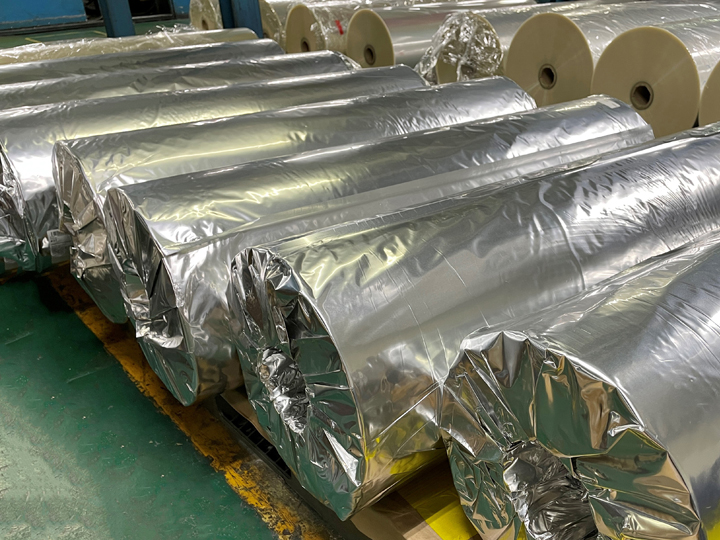

We will process to cellophane arrived from a specialized factory. The surface of cellophane is coated with a release agent, the primer agent on the reverse side, and an adhesive, and it becomes a tape of 4 layer structure. Dry in dryer and take up.

Cut the tape wound on a long rubber tubular winding core to a certain width so as to cut the roll cake. We inspect the weight in order to make sure haw many are packed in one package and pack in a box. Self Adhesive Cellulose Tape stored in warehouse will be shipped worldwide in order.

see moreCutting process is necessary for a different sizes of adhesive tape ; to serve customers’ various requirement and for more convenience application.

Next process from cutting is Packing for distribution and to protect Goods from any damaging and maintain goods quality.

Final process is Delivery to distributor/customer both domestic and international upon requirements. Due to UTN has certified by ISO 9001 , ISO 14001 and AEO, Please be assured that our Goods are precise and perfect as we are determined.